- About Us

- Address:Xinzheng City,HN Province,CN

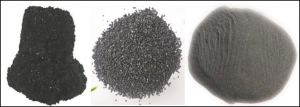

Green Silicon Carbide

Professional Service

With nearly two decades of production experience, we provide dedicated account managers for both pre-sales and after-sales support, ensuring your procurement experience is completely worry-free.

Product Features

Green Silicon Carbide is characterized by:

-

Green color with crystalline structure

-

Strong cutting ability

-

Stable chemical properties

-

Excellent thermal conductivity

Technical Properties:

-

Crystal structure: Hexagonal

-

Mohs hardness: 9.2

-

Micro hardness: 3100–3400 kg/mm²

-

Hardness: Higher than corundum, second only to superhard abrasives such as cubic boron nitride, boron carbide, and diamond

Production Process:

Green Silicon Carbide is produced using petroleum coke and high-quality silica as the main raw materials, with salt as an additive, and obtained through high-temperature melting in a resistance furnace.

Product Specifications

-

JIS 240# – JIS 6000#

-

F230# – F1200#

-

P240# – P2500#

Product Usage

Widely applied in:

-

Cutting and grinding of solar silicon wafers, semiconductor silicon wafers, and quartz chips

-

Polishing of crystal and steel

-

Precision polishing of ceramics and special steels

-

Production and application of consolidated abrasives, free cutting, grinding, and polishing tools

-

Manufacturing of advanced refractory materials, engineering ceramics, heating elements, and thermal energy components

Plsease input value

Error E-mail format

Plsease input value