- About Us

- Address:Xinzheng City,HN Province,CN

Semi-brittle Corundum

Professional Service

With nearly two decades of production experience, we provide dedicated account managers for both pre-sales and after-sales support, ensuring your procurement experience is completely worry-free.

Product Features

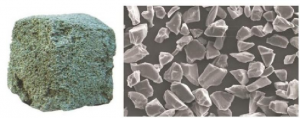

Semi-brittle corundum is made from high-quality bauxite. On the basis of sub-white corundum smelting, by adjusting the smelting process and ratio, and melting at high temperature above 2000℃ in an arc furnace, it is produced through a special crushing process.

Because its brittleness and toughness are between white corundum and brown corundum, it is called semi-brittle corundum.

Key Characteristics:

-

High temperature resistance

-

Corrosion and erosion resistance

-

Low porosity and stable thermal performance

-

Abrasive grains with good self-sharpness → sharp cutting ability without burning the workpiece

-

Improved abrasion resistance after further processing

Application Advantage:

Especially suitable for grinding of:

-

Heat-sensitive steels and alloys

-

Non-ferrous metals (aluminum, copper, zinc, lead)

-

Non-metallic materials (wood, plastic)

It is also widely used in the production and manufacture of consolidated abrasives.

Our company maintains a long-term cooperation with Guizhou Dazhong Seventh Grinding Wheel Co., Ltd., who use semi-brittle corundum and calcined semi-brittle corundum as raw materials to produce a series of semi-brittle corundum micropowders.

Product Specifications

-

Standard / Specification:

-

JIS 240# – JIS 6000#

-

F230# – F1200#

-

Product Usage

-

Grinding of heat-sensitive steels and alloys

-

Non-ferrous metals: aluminum, copper, zinc, lead

-

Non-metallic materials: wood, plastic

-

Widely applied in consolidated abrasives manufacturing

Plsease input value

Error E-mail format

Plsease input value